DIBOND® Aluminum Composite Panels

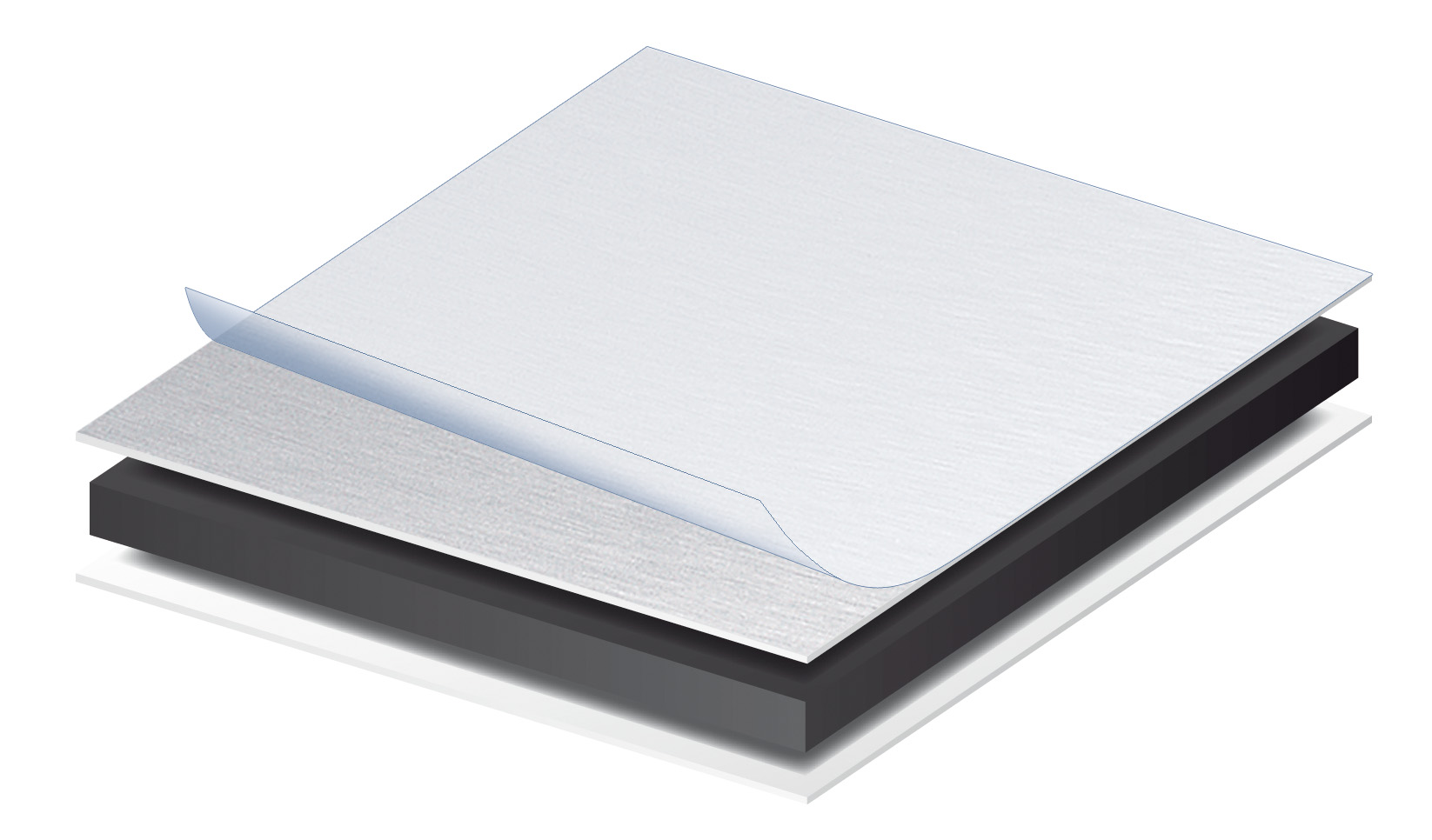

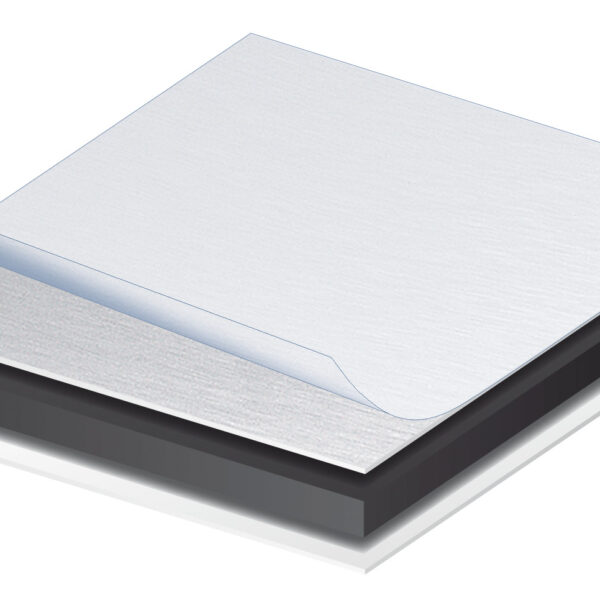

DIBOND®, the world’s first aluminium composite sheet which is specially optimised for display. It is light and can be 3-dimensionally shaped, making it extremely stable and rigid. DIBOND® is ideally suitable for internal and external applications and can be used for an extraordinary variety of surfaces.

- Unique AlMg1 alloy gives stability, particularly high corrosion-resistance and excellent capabilities for further processing.

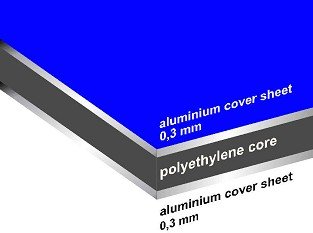

- The black polyethylene core gives stability and optimises long-term performance for outdoor use.

- Special polyester paint systems compliant with ECCA standards provide absolute flatness, optimum printability and consistently high colour quality. They are free from heavy metals and conform to REACH, RoHS and WEEE.

PROCESSING

- Digital printing | Screen printing

- Contour milling

- Water jet cutting

- Shearing | Sawing | Die cuting

- Glueing

- Drilling | Riveting | Screwing

- Welding

- Folding (V-groove) | 3D

- Cold bending | Cold folding

- Engraving (laser / graver)

Description

DIBOND®, the world’s first aluminium composite sheet which is specially optimised for display. It is light and can be 3-dimensionally shaped, making it extremely stable and rigid. DIBOND® is ideally suitable for internal and external applications and can be used for an extraordinary variety of surfaces.

- Unique AlMg1 alloy gives stability, particularly high corrosion-resistance and excellent capabilities for further processing.

- The black polyethylene core gives stability and optimises long-term performance for outdoor use.

- Special polyester paint systems compliant with ECCA standards provide absolute flatness, optimum printability and consistently high colour quality. They are free from heavy metals and conform to REACH, RoHS and WEEE.

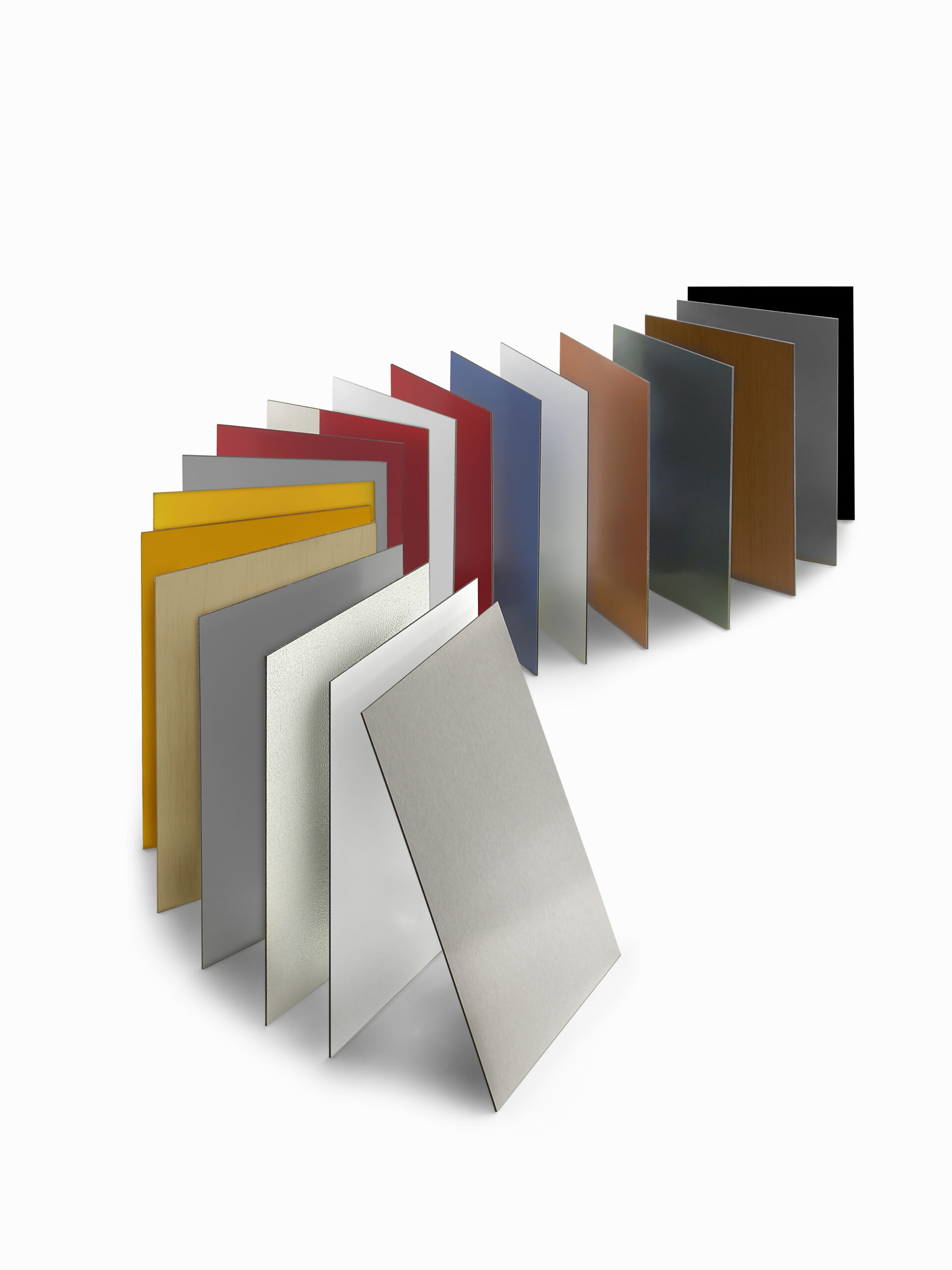

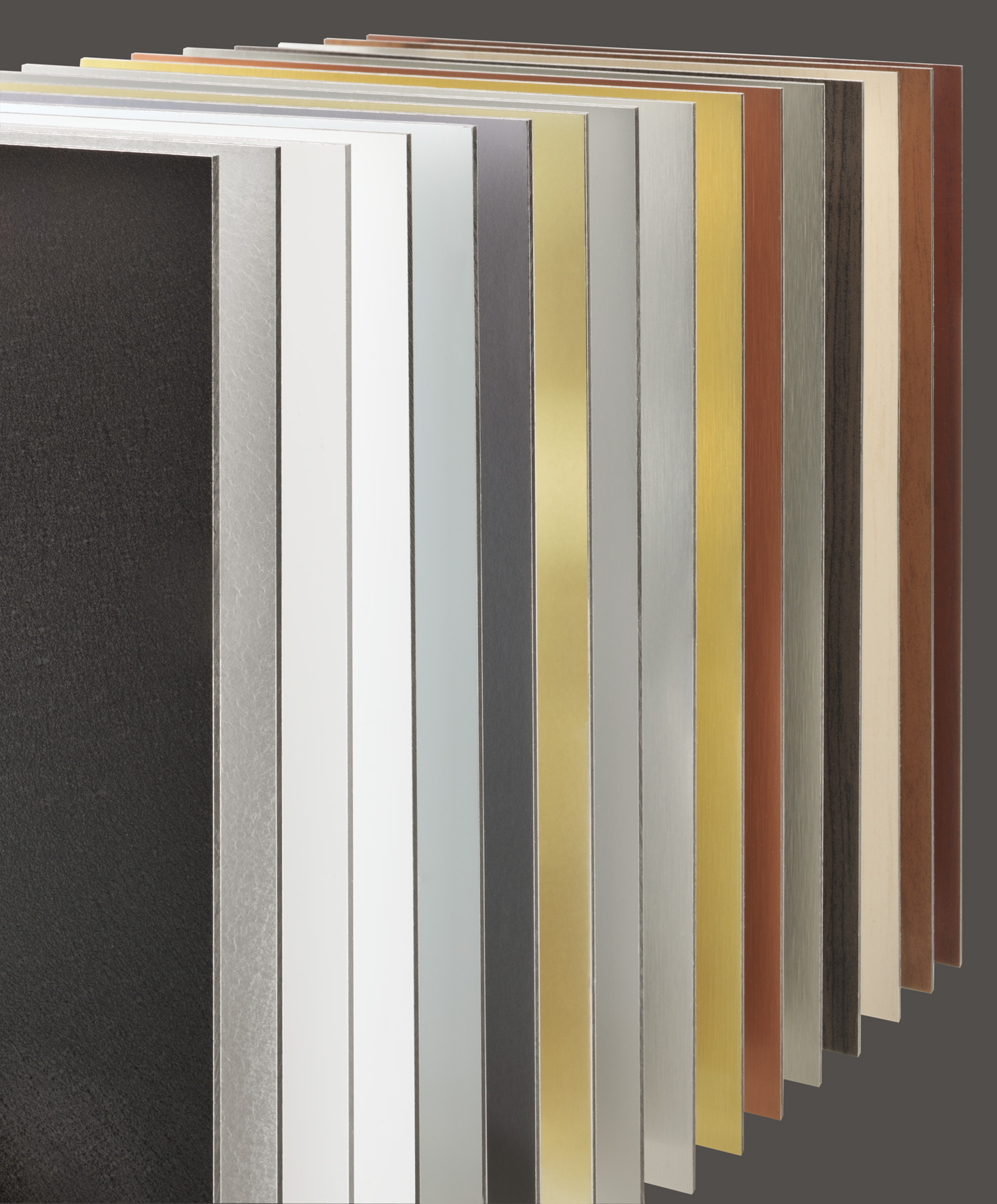

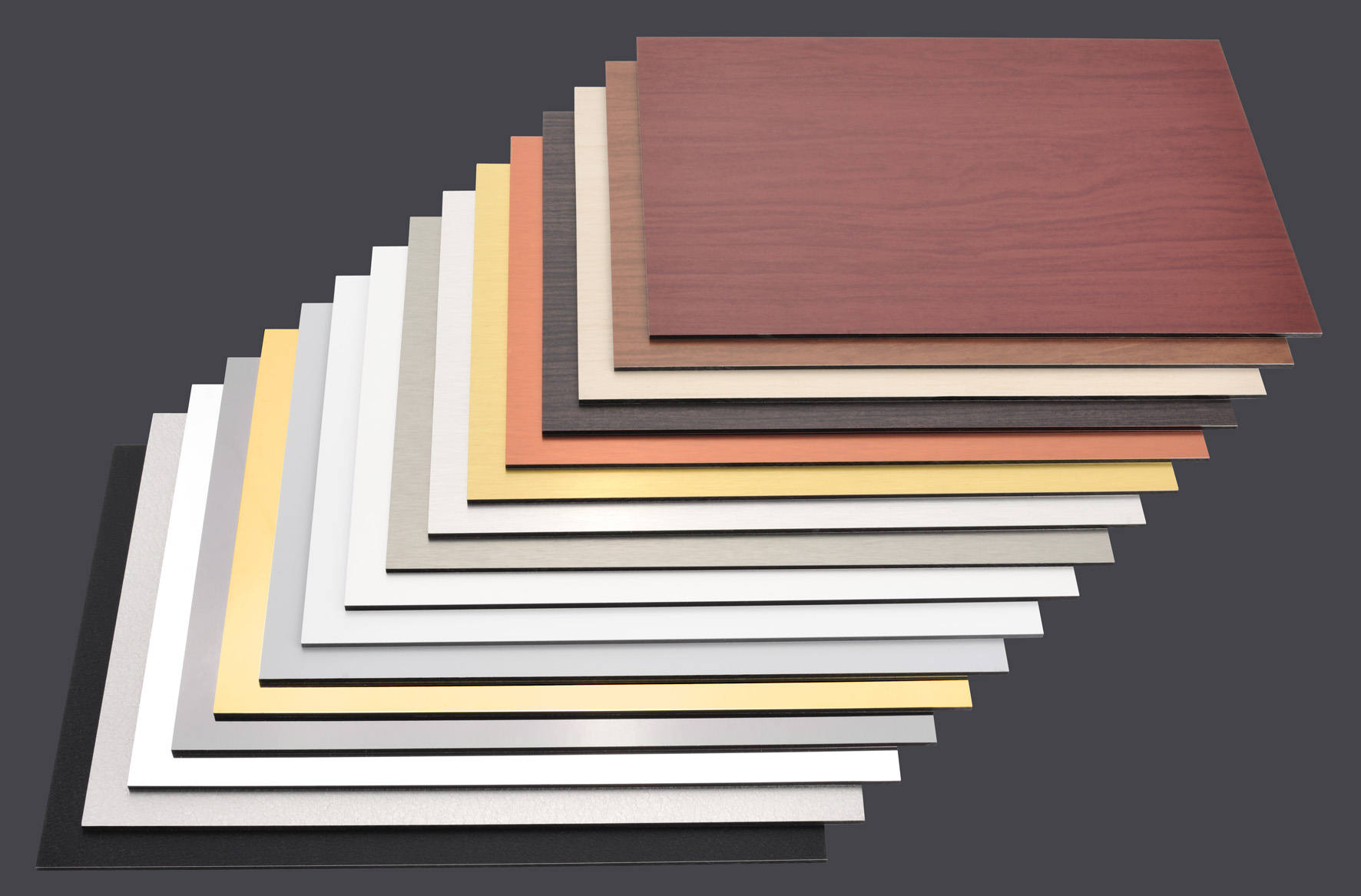

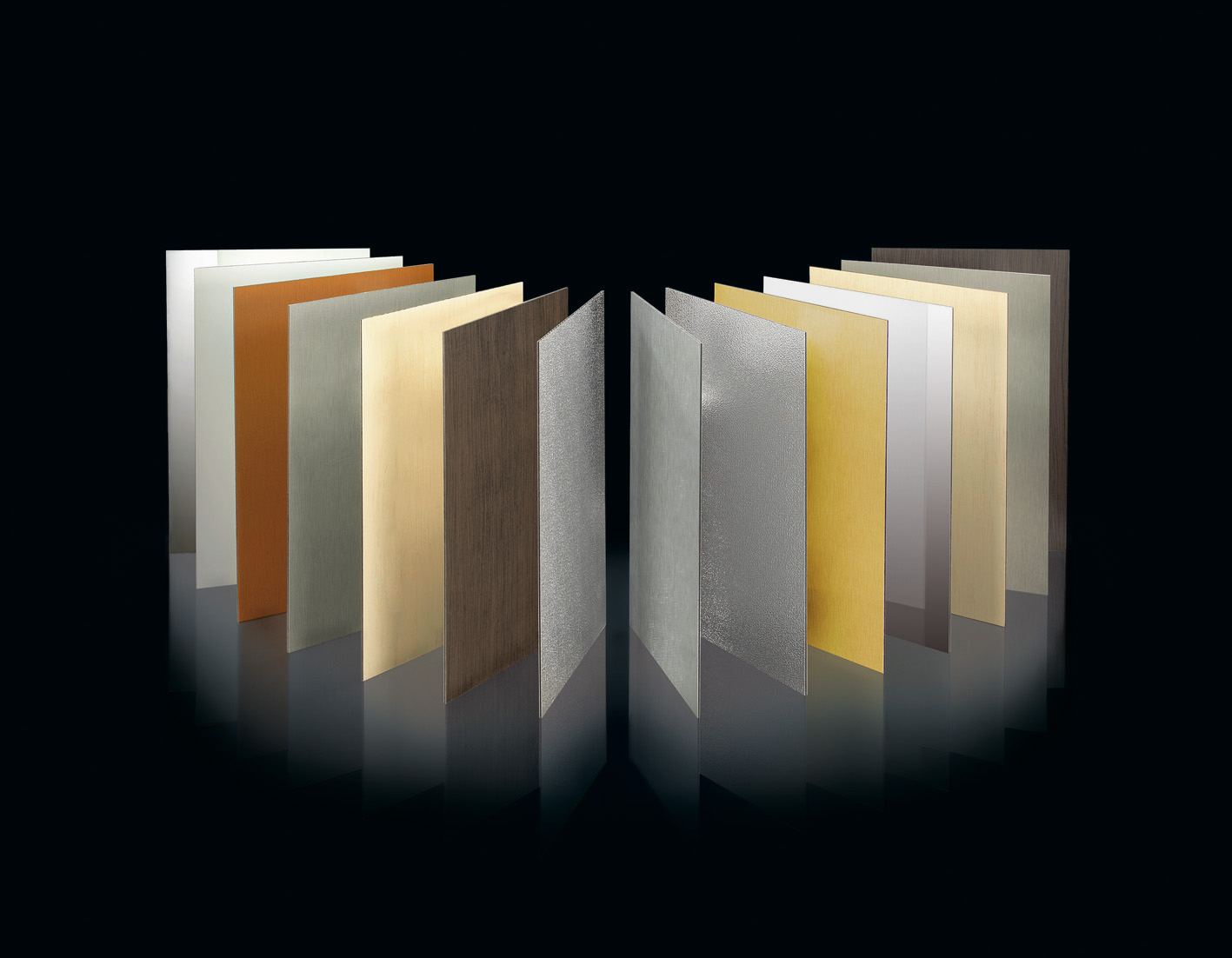

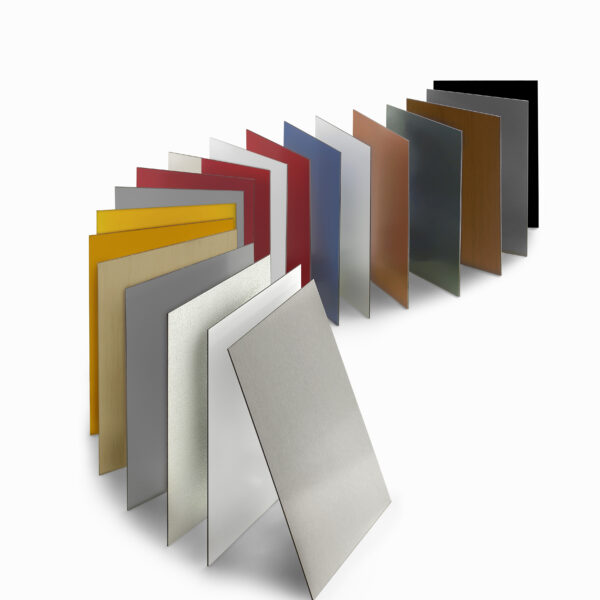

PRODUCT VARIANTS

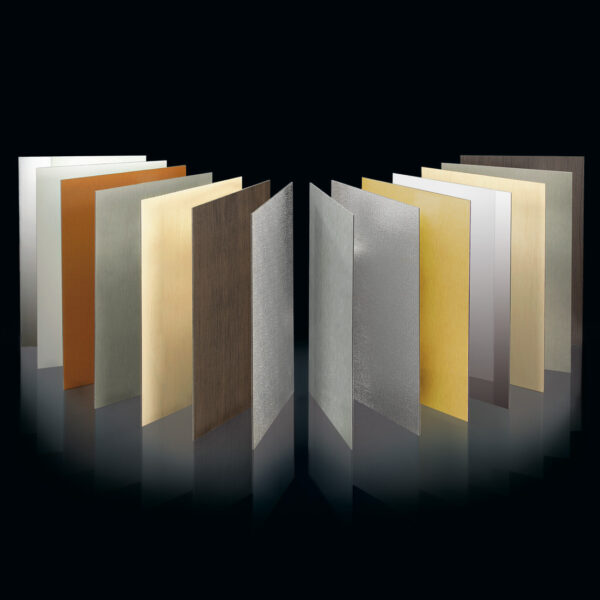

DIBOND®metalllics

High-gloss, metallic surfaces for unique highlights in retail. The new DIBOND®metallics color series offers shop fitters & designers fresh creative options. The shimmering effect featured in the exclusive, high-gloss, surfaces in four coordinating colours, radiant yellow, sparkling red, sophisticated anthracite and glamorous white-silver, is impressive.

DIBOND®FR

DIBOND®FR aluminium composite sheets have the fire classification “fire retardant” because of their mineral core. DIBOND®FR now available in new 2050 mm width.

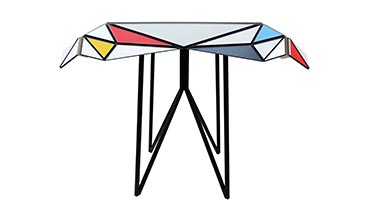

DIBOND®design

Unlimited design freedom to express your individual style. Design your individual decor and we will realise your concept on the object of your choice.

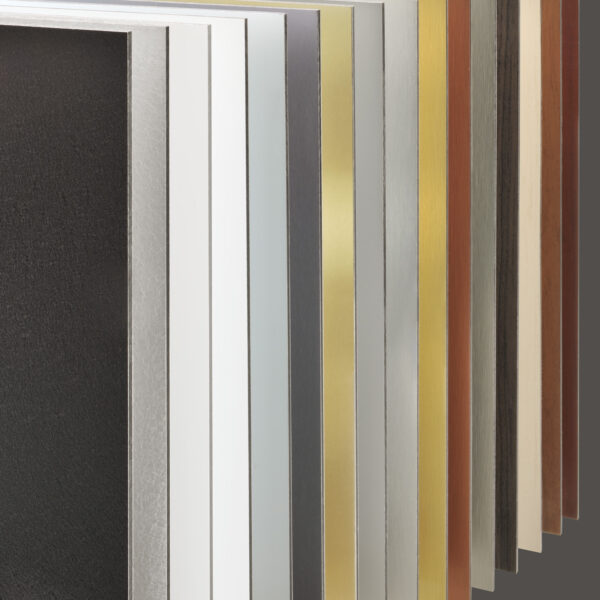

BUTLERFINISH®

The characteristic brushed effect of BUTLERFINISH® is due to a special surface polishing process in which the cover sheet is first run through rollers and then stove-enamelled with clear lacquer.

DIBOND®digital

A specific paint system guarantees the best ink adhesion for UV-curable and solvent-based inks. The combination of this paint system and the extremely flat surface of DIBOND®digital not only enables the reproduction of very fine lines and structures but also allows faster printing.

DIBOND®decor

DIBOND®decor is our name for DIBOND® surfaces with a wood-look finish. These surfaces score in places where a combination of elegant wood-look and creative finishing are called for.

DIBOND®mirror

This mirrored surface for display areas has reflective qualities which are similar to those of a conventional mirror; it is unbreakable, however, and is only half as heavy.

DIBOND®structure

DIBOND®structure gets its characteristic look from a special paint system which gives the plate a haptic surface. With the option of a black or a silver surface, DIBOND®structure creates special accents.

DIBOND®eloxal

DIBOND®eloxal surfaces are coated in a special process with a 5 μm or 10 μm thick anodised coating which makes them significantly harder than surfaces finished using a paint system.

Dimensions

Thicknesses: 2.0 – 6.0 mm

Sheet Dimensions: 1500x3050mm (Dibond® mirror 1250x3050mm)

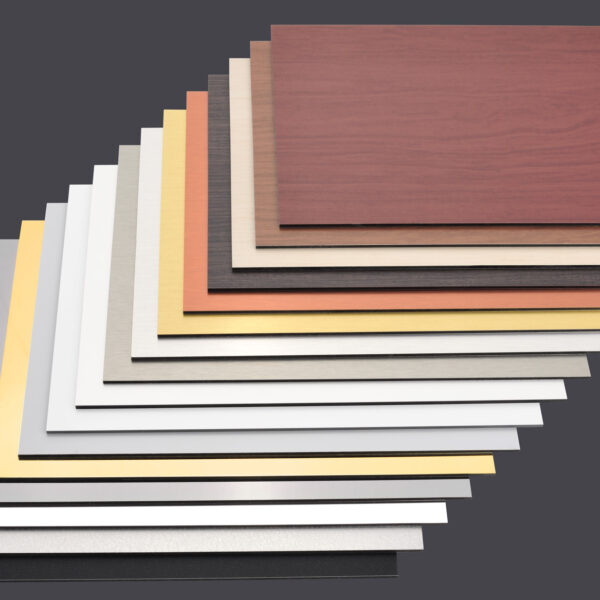

Colors

STANDARD COLORS

matt/matt | gloss/matt | gloss/gloss

Buttlerfinish®

Dibond® Structure

Dibond® mirror

Dibond® décor

Dibond® design

Dibond® digital

Dibond® eloxal

Dibond® FR

Dibond® metallics

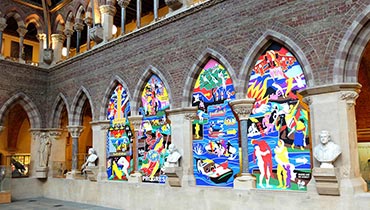

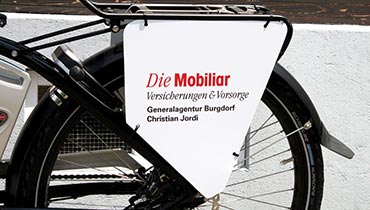

Applications

APPLICATIONS

- Displays (POS / POP)

- Signage | Lettering

- Corporate Identity

- Shop design | Shop window decoration

- Furniture construction | Interior design

- Exhibition design

- Creative work

Technical Specifications

| THICKNESSES AND WEIGHT | |||||

| Panel thickness | mm | 2 | 3 | 4 | 6 |

| Thickness of aluminium layer | mm | 0.3 | |||

| Weight | kg/m² | 2.9 | 3.8 | 4.75 | 6.6 |

| CORE | |||||

| Polyethylene, type LDPE | g/cm³ | 0.92 | |||

| SURFACE | |||||

| Lacquering | Modified-Polyester-Coating | ||||

| Gloss (Initial value) | % | 25 – 85 | |||

| MECHANICAL PROPERTIES | |||||

| Section Modulus (W) | cm³/m | 0.5 | 0.8 | 1.1 | 1.7 |

| Rigidity (E∙I) | kNcm²/m | 345 | 865 | 1620 | 3840 |

| Alloy of aluminium layer | EN AW-5005A (AlMg1), H44 according EN 485-2 | ||||

| Modulus of Elasticity | N/mm² | 70’000 | |||

| Tensile strength of aluminium | N/mm² | Rm 145 – 185 | |||

| Proof Stress | N/mm² | Rp0,2 110 – 175 | |||

| Elongation | % | A50 ≥ 3 | |||

| Linear Thermal Expansion | 2.4 mm/m at 100°C temperature difference | ||||

| ACOUSTICAL PROPERTIES | |||||

| Sound Absorption Factor (αs) | 0.05 | ||||

| Sound Transmission Loss (Rw) | dB | 23 | 24 | 25 | 26 |

| Loss Factor (d) | 0.0048 | 0.0057 | 0.0072 | 0.0102 | |

| THERMAL PROPERTIES | |||||

| Thermal Resistance (1/λ) | m²K/W | 0.0047 | 0.0080 | 0.0113 | 0.0180 |

| Thermal Transmission Coefficient (k) | W/m²K | 5.72 | 5.61 | 5.50 | 5.30 |

| Temperature resistance | °C | -50…+80 | |||